Ecodry 4DK: innovative adiabatic cooler

A centralized closed-circuit adiabatic cooling system designed to save water and energy

One tool for all your metrics

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt.

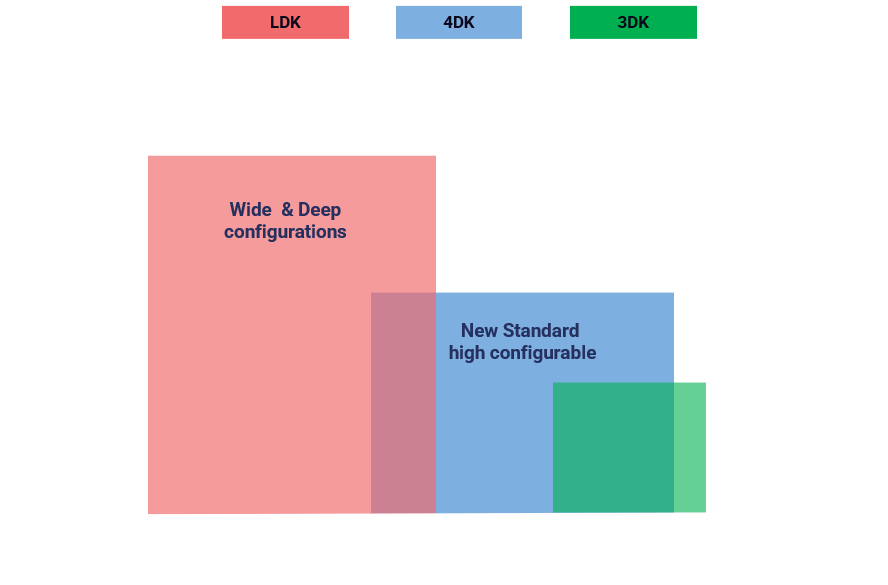

Pioneering the adiabatic cooling technology, 4DK is the latest evolution of Ecodry Systems.

Energy saving

New level of efficiency with higher performance thanks to Energy savings up to -40%.

Water saving

Optimized to deliver long-term savings in water. Minimum Water Footprint, up to 95%.

Carbon footprint

Designed for health and safety, with a riduced maintenance costs and carbon footprint up to -40%.

Industries

Due to its unique design, 4DK achieves a fluid outlet temperature close to the wet bulb temperature (3-4K).

By taking advantage of adiabatic cooling, it optimizes the water and energy balance, providing a high-performance solution in various applications. 4DK from Frigel offers a modular range for perfect adaptation to the customer's system. Improve your cooling with 4DK from Frigel.

Industries

APPLICATIONS WE FOCUS: Injection Molding (automotive, packaging, medical, etc.), Food & Beverage, Air Compressor Cooling, Data Centers, Free Cooling, Machine Cooling, Power Generation Processes, High temp. applications, Other Industrial Processes.

Improve efficiency measures across the board with the new ECODRY 4DK

COP (COEFFICIENT OF PERFORMANCE)

UP TO 30%

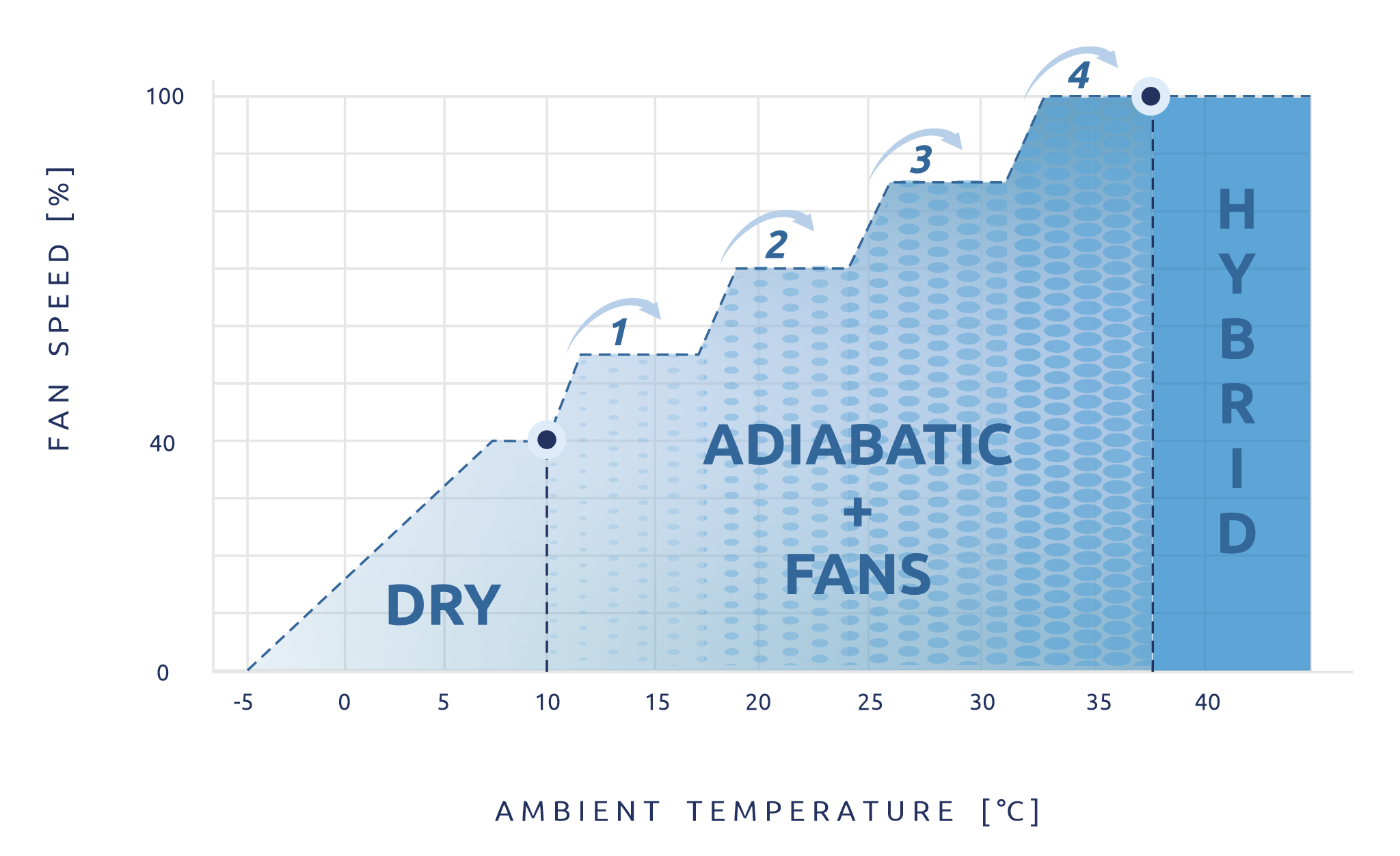

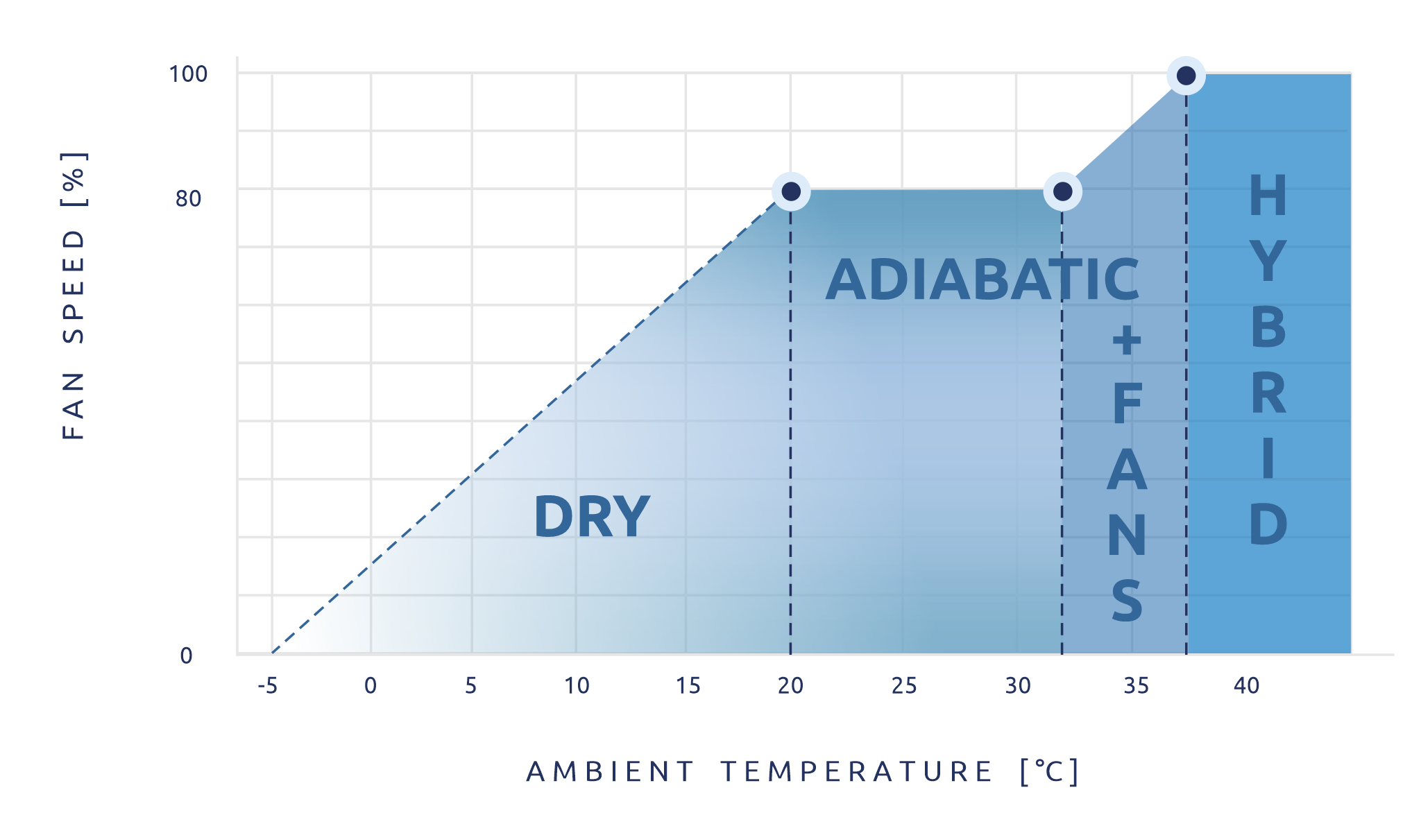

Less energy consumption required thanks to the optimized Dry and Wet operating mode throughout the year.

SATURATION EFFICIENCY

UP TO 80%

The gain is maximized in water efficiency through intelligent management of the adiabatic system.

HIGH POWER DENSITY

UP TO 35%

Less footprint required thanks to the unique design of air intake from underneath and no air flow recirculation between units.

Energy saving

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Ultricies leo integer malesuada nunc vel risus commodo viverra. At erat pellentesque adipiscing commodo elit at.

WHITEPAPER

Get our free ebook on how you can level up your B2B SaaS content marketing

Get our free ebook on how you can level up your B2B SaaS content marketing

Water saving

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Ultricies leo integer malesuada nunc vel risus commodo viverra. At erat pellentesque adipiscing commodo elit at.

WHITEPAPER

Get our free ebook on how you can level up your B2B SaaS content marketing

Get our free ebook on how you can level up your B2B SaaS content marketing

Carbon footprint

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Ultricies leo integer malesuada nunc vel risus commodo viverra. At erat pellentesque adipiscing commodo elit at.

WHITEPAPER

Get our free ebook on how you can level up your B2B SaaS content marketing

Get our free ebook on how you can level up your B2B SaaS content marketing

Energy saving

Optimizing resource saving without losing cooling efficiency has become a key issue for plant managers and the engineering firms that support them.

Whether your application is cooling water/glycol for water cooled chillers, injection molding machines or any other process, Frigel can recommend the most suitable adiabatic cooling solution to meet your energy saving requirements.

Frigel’s Adiabatic Cooling System brings significant water savings and energy efficiency in comparison with a conventional cooling tower.

For more details download the whitepaper here below, and please feel free to contact us.

DRASTIC ENERGY SAVINGS

Maximizing resource efficiency without compromising the effectiveness of cooling holds paramount importance for plant managers and engineering firms providing support.

The cooling system assumes a critical role in cost reduction while adhering to sustainable principles.

Water saving

Evaporative cooling towers are used in a wide range of industries and result in the greatest use of water in industrial and commercial applications.

While all cooling towers continuously recirculate water, a substantial portion is constantly evaporated and otherwise dispersed into the environment.

However, alternative technologies, such as the latest generation adiabatic coolers, can drastically reduce water consumption by up to 90-95% and even more, depending on the application and local climate conditions.

HOW CAN WE SAVE WATER?

A brief analysis of the water consumption of both cooling towers and adiabatic coolers with a comparison of the results.

The cooling system assumes a critical role in water savings.

Carbon footprint

The carbon footprint is an environmental indicator that measures the impact of human activities on the global climate and expresses quantitatively the effects produced by so-called greenhouse gases (GHGs) in terms of carbon dioxide equivalent (CO 2 -eq). This is calculated by multiplying the emissions of each of the greenhouse gases by its warming potential (GWP).

The standard is based on the Life Cycle Assessment (LCA) methodology, a standardized methodology (ISO 14040 and ISO 14044) by which all analyzed all processes related to the product/service, from the extraction of the raw materials, through to end-of-life management.

HOW CAN YOU EMBRACE A LOW-CARBON FUTURE?

An in-depth article on how the adiabatic solution contributes to carbon footprint reduction and what Frigel's proposal is with the innovative Ecodry 4DK.

The in-depth article will be available soon, please contact us clicking the button below.

What our experts say

“Our goals are focused on sustainability. We have created a solution to help future customers keep up with their competitors through increased operational efficiency: more water savings, more energy savings and a better compliance with national anti-legionella regulations, all while reducing investment costs in €/kW for our customers.”

“New Ecodry 4DK is the last step of the evolution scale of Ecodry platfrom. Products with a proven history of success that today with 4DK and LDK new efficiencies paradigmas can help industries and people to offord all new booming challenges of water savings and energy savings.”

“Thanks to the new development and evolution of the 4DK, Frigel once again positions ECODRY as the best technology available in the adiabatic air cooler segment. In my opinion, the 4DK is the best and most advanced air cooler ever built. Saving water and energy is the next global challenge, for every single company.”

“We wanted to bring into the product our 20+ years of experience with the adiabatic closed-loop technology applied to process cooling, from the performance and application modeling to the use and maintenance of the product.”

“After so many years on the technology edge, you can hardly believe a product can be pushed further, but this is exactly what's happening now: not only a new name but a brand new "sound" in the engine of this incredible travelling companion if you are thinking about where you're going next, make sure you have the right tool to get there!”

“With the new Ecodry 4DK we decided to rethink the core of the machine: the intelligent digital control of 4DK meets the maket demand in term of reliability, flexibility and smart remote control, with a costant focus on sustainability, demonstrating that Frigel is always a solution ahead."

FAQ

What are the main benefits of 4DK?

Just to highlight 3 out of severals:

-

High level of modularity with compact design

-

Self draining function for Glycol-free systems

-

High peak load offset safety

Why is 4DK so efficient?

-

The dry-adiabatic hybrid concept of 4DK is totally managed by intelligent system control, the control logic optimizes the liquid coolers for each individual application, taking into account the annual variation of the temperature at the site and the expected load profile, giving priority to energy saving or water consumption.

-

Due to the lower operating costs, the payback period is quite short.

How long (in general) do Adiabatic pads last?

Typically the longevity of the equipment is predominantly a function of water and air quality, as well as proper operation. With 4DK we focused on high quality material such as SS304L for casing, high premium Pads for long lasting performances with minimized maintenance. All in all the design is made for high reliability, if you think you need a replacement.

Meet our Engineers at upcoming events

K-SHOW

Germany (Dusseldrf). Frigel presents its innovative Thermal Control Technology focused on Cycle Time Reduction.

INTERPLAST

Thailand (Bangkok). Frigel's Thermal Control Solutions & Ecodry Coolers for the Asian market.

FAKUMA

Germany (Friedrichafenn). Frigel's Innovative Process Cooling Solutions focused on Plastic Industries.

DATA CENTRE WORLD

England (London). Frigel's Innovative Adiabatic Cooler Solutions focused on Datacenters.

Syncro technology to improve quality and production

SOLUTION

GelliPlast, like Frigel, confirms itself as a company focused on customer care.

IMPACT

It dedicates significant investments in cutting-edge technology, analysis and research.

Syncro technology to improve quality and production

SOLUTION

GelliPlast, like Frigel, confirms itself as a company focused on customer care.

IMPACT

It dedicates significant investments in cutting-edge technology, analysis and research.

Syncro technology to improve quality and production

SOLUTION

GelliPlast, like Frigel, confirms itself as a company focused on customer care.

IMPACT

It dedicates significant investments in cutting-edge technology, analysis and research.