LDK Ecodry

The new generation of adiabatic coolers

A new range

takes shape

Frigel have always been at the forefront of innovation, driven by the challenging target to improve the competitiveness of our customers and by the respect for the environment. Now we enter a new era, when a completely new product range is being unveiled for the benefit of our existing and future clients as well as of Mother Nature.

Proven track record

Pioneer in Adiabatic Cooling solutions

Every drop of water saved; every kW of electricity spared makes a difference. Frigel’s contribution to our future by reducing water consumption in Process Cooling can be counted in millions of cubic-meters. Thanks to the precise control of our units, their energy consumption is kept at minimum. We have delivered more than 9000 adiabatic coolers called Ecodry to more than 100 different Countries in the last 25 years.

Here and now

A new range of adiabatic coolers is born

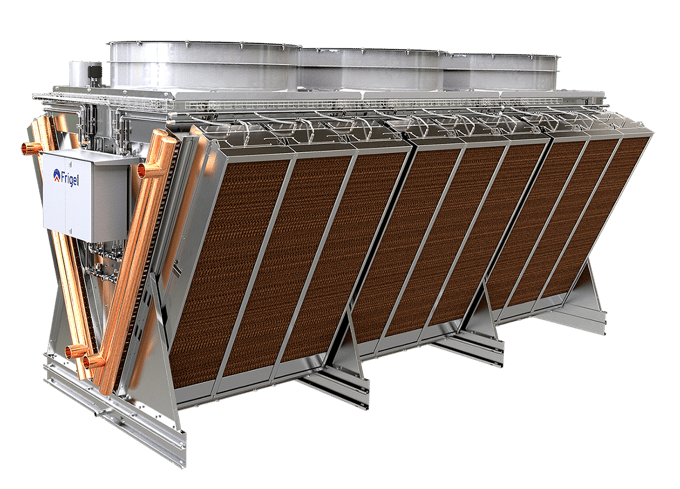

We have launched the Ecodry – LDK, the first member of the new platform. We have built on our vast experience and added new features, requested by the market. With our modular set-up, we can cover a capacity range from 400 – 2800 kW. Industrial design, industrial execution for medium and heavy-duty cooling. Patented solutions will keep your carbon and water footprint low.

Raising the bar

Save more Energy, more water, more footprint

This rock solid basis allows us now to enter into new industries. With the ultimate generation of adiabatic coolers we create a platform which will be able to meet the requirements of challenging applications and capacities, by providing the well-known Frigel benefits. No matter which sector you are in, we will have a solution for You.

Features

Better cooling performance

Carbon Footprint

Water Savings

New standards in terms of environment impact

Connectivity

Energy saving

Pillars of a new adiabatic

cooling Era: LDK

Energy saving

Water saving

Carboon footprint saving

Take care

Easy maintenance

Dynamic optimization

Sustainability

-95%

Reducing water

consumption

80%

Reducing maintenance

& operating costs

100%

Clean water to process

No aerosol or Plumes

Ecodry LDK at a glance

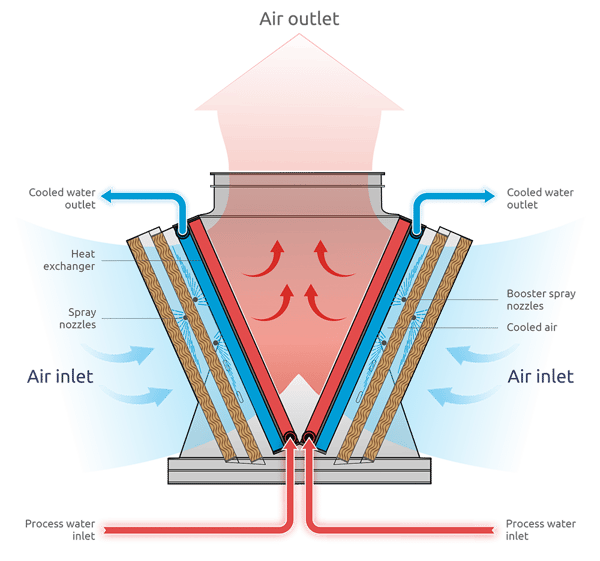

From Dry - Spray - Adiabatic to Hybrid technology

Frigel have always been at the forefront of innovation, driven by the challenging target to improve the competitiveness of our customers and by the respect for the environment. Now we enter a new era, when a completely new product range is being unveiled for the benefit of our existing and future clients as well as of Mother Nature.

Up to 2,8MW single unit in adiabatic mode

Up to 1.8MW as single dry cooler

Modular System Design -Wide and Deep

Industries

Energy efficiency simply means using less energy to accomplish the same task, which is to eliminate wasted energy. There are huge opportunities for efficiency improvements in every industry, be it power generation, gas turbine, transmission grids, data centers, industrial process cooling, metals, Organic Rankine Cycle (ORC), Air Compressor cooling, industrial HVAC.

Efficient - Sustainable and Patented

Coolpad TM

The unique design gives it a high strength and durability with exceptional cooling and humidification rates.

Greater Efficiency

Long lasting performance

Recyclable at end of life

Hygienics rules compliant

Minimized Operating costs

Algae and weather resistant

Prevent bacterial proliferation

Scrubbable to extend service life

Reinforced Flame retardant material

GreenGuard Gold certified

Use of Computational Fluid Dynamics (CFD) for performance optimization

The use of modern powerful CFD simulation tools, combined with the expertise of design and R&D engineers, allowed to have a wide overview on a multitude of design aspects involved in the development process

%20for%20performance%20optimization%20of%20the%20Frigel%20LDK%20adiabatic%20cooling%20system.png?width=300&height=212&name=Use%20of%20Computational%20Fluid%20Dynamics%20(CFD)%20for%20performance%20optimization%20of%20the%20Frigel%20LDK%20adiabatic%20cooling%20system.png)

What’s inside:

1. What is CFD?

2. What are the benefits of using CFD during product development?

3. Application of CFD to the development of the Frigel LDK adiabatic cooling system

The most efficient Adiabatic Cooler

ECODRY - LDK

- The ultimate cooling solutions

- Toward more efficient Heat Rejection

- Dry - Spray - Adiabatic - Hybrid

What’s inside:

1. The natural choice over evaporative cooling towers: LDK vs Cooling Towers

2. CoolPad the most Efficient adiabatic system

3. Highlights

4. Main industrial components

Passive Liquid Cooling enables a carbon free 350kW Modular Data Centre

Passive Liquid Cooling appeared recently on the crossroad of multiple trends in the data center industry. The growing power of chips and servers requires a transition from air cooling to liquid cooling, but ecological limits and data centers practice need a simple solution with minimal energy and water spending.

With no pumps or drip connections inside LDK Adiabatic Cooler is able to serve all types of Data Centers (colocation, cloud and HPC) the most efficient way with no risk of leakage and no complicated maintenance.

Optimization of water spray system with CFD

To ensure performance and environmental sustainability of products is nowadays fundamental not only for the success on the market but, mostly, for ethic reasons.

Nothing to chance in our nebulization system:

1. CFD for optimizing type, shape, direction of nozzle.

2. CFD for simulating jet, cone, droplet size, flow, pressure, and water quantity.

3. Simulation-driven R&D for proper redistribution of water and effective evaporation.