Microgel Syncro RSY

Innovative synchronized cooling.

The easiest and fastest way to boost your process.

One tool for all your metrics

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt.

Microgel Syncro RSY is Frigel's latest technology milestones for injection process cooling.

Cycle time reduction

The cooling is optimized via synchronization, with cycle time reductions up to 40%.

Improved part quality

The synchronized control enables advantages in terms of quality of the parts.

Energy saving & efficiency

New level of efficiency with lower specific energy consumption up to 23%.

Industries

APPLICATIONS WE FOCUS: Injection Molding (automotive, packaging, medical, etc.), Food & Beverage, Air Compressor Cooling, Data Centers, Free Cooling, Machine Cooling, Power Generation Processes, High temp. applications, Other Industrial Processes.

Synchronized Control

The cooling approach evolved with a core integration between the mold temperature control system and the injection process.

CYCLE TIME REDUCTION

The mold cooling follows the cycle according to the needs of the process, solving the typical trade-off of water temperature control technical injection molding, this turns into cycle time reduction.

EASE OF USE

Via an intuitive and user friendly HMI, the setup of the Syncro RSY is carried out in a short time. The machine has a recipe database and an online wizard for the fine-tuning of the unit.

PROVEN RESULTS

A periodic performance report of the machine is sent to the user, in order to keep track of the cycle time reduction, energy consumption and proven performance.

ROI: COMPETITIVE RETURN ON INVESTMENT

With such a significant cycle time reduction, the return of investment is guaranteed in few months. The increase of the injection machine productivity turns into a lower CAPEX for new IMMs.

PART QUALITY MATTERS

Syncronized cooling enables a more sophisticated cavity cooling, reducing imperfections on product surfaces, with better part dimensional stability.

LOWER SPECIFIC ENERGY CONSUMPTION

The reduction of cooling time enables a lower Specific Energy Consumption in terms kWh/kg, this turns into energy savings on the single unit of up to 23%.

Energy saving

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Ultricies leo integer malesuada nunc vel risus commodo viverra. At erat pellentesque adipiscing commodo elit at.

WHITEPAPER

Get our free ebook on how you can level up your B2B SaaS content marketing

Get our free ebook on how you can level up your B2B SaaS content marketing

Water saving

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Ultricies leo integer malesuada nunc vel risus commodo viverra. At erat pellentesque adipiscing commodo elit at.

WHITEPAPER

Get our free ebook on how you can level up your B2B SaaS content marketing

Get our free ebook on how you can level up your B2B SaaS content marketing

Carbon footprint

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Ultricies leo integer malesuada nunc vel risus commodo viverra. At erat pellentesque adipiscing commodo elit at.

WHITEPAPER

Get our free ebook on how you can level up your B2B SaaS content marketing

Get our free ebook on how you can level up your B2B SaaS content marketing

Cycle time reduction

The injection molding process can be divided into five separate steps: plastification injection, holding, cooling and finally ejection.

The impact of mold cooling on the cycle time can reach up the 60%. The mold has to be cooled or heated, traditionally done with a Temperature Control Unit (TCU).

For this reason Frigel developed Microgel Syncro RSY.

For more details: download the whitepaper and contact us.

CYCLE TIME REDUCTIONS AND PRODUCTIVITY IMPROVEMENT WITH SYNCHRONIZED COOLING

The thermoregulation of the mold of technical parts injection molding process has always been a tricky challenge for mold, IMM manufacturers and end users.

Competitive return of investment

Advanced mold Temperature Control Units are the best opportunity to increase productivity with low impact on CAPEX, from 5 to 15%. The guaranteed cycle time reduction by the new Microgel Syncro RSY technology turns into an extremely short Payback time of average 9 months.

Our customers, after testing new Syncro technology, reported a significant advantage in terms of profitability impact. Each Injection Molding Machine where Syncro unit is used gains some free time for additional production.

For more details download the case studies and contact us.

HOW A SMALL INVESTIMENT ON THE TEMPERATURE CONTROL UNIT ENHANCES A COMPANY PRODUCTIVITY

GelliPlast has chosen Microgel™ Syncro technology to improve quality parts and production.

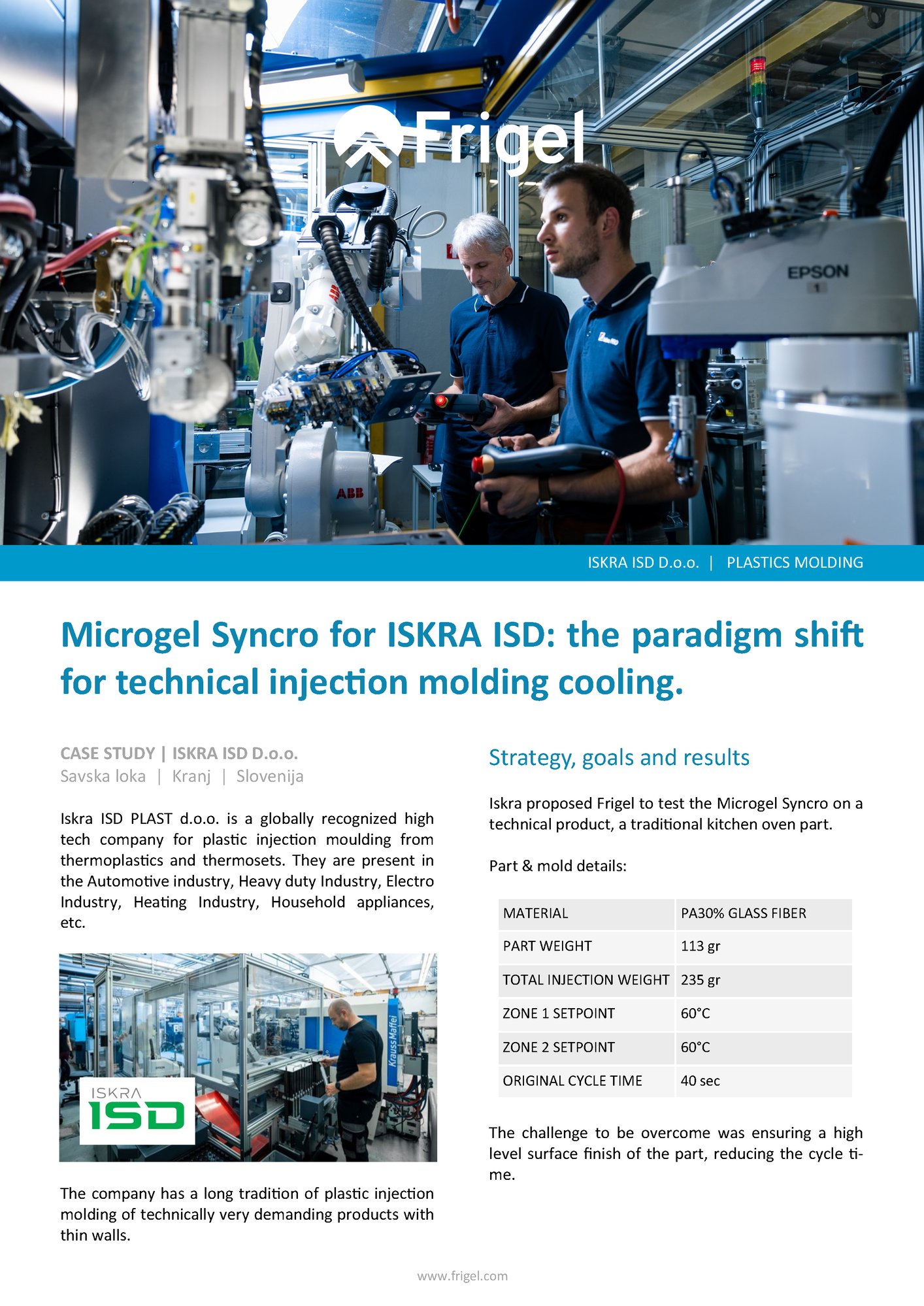

ISKRA has confirmed Microgel™ Syncro technology thanks to the +42% increase of productivity achieved.

Quality improvements

Syncro technology is based on the easy concept to provide the right amount of thermal energy - that is cooling or heating - only at the right time.

This behavior of the machine turns into quality advantages such as more accurate reproduction of surface details, shiny gloss parts, better dimensional part stability, improved mechanical resistance etc., etc.

For more details download the report and contact us.

Energy saving & efficiency

Energy is one of the key variable to consider in the design of a new TCU. Syncro technology has inverter pumps, power meter and flowmeters installed as standard.

The power meter measures the instant power adsorption and the energy used in every production session.

The Specific Energy Consumption SEC [kWh/kg] is calculated in syncro mode and kept under control with the performance report.

For more details, download the report and contact us.

ENERGY CONSUMPTION KPI UNDER CONTROL

Syncro technology guarantees an average energy consumption lower than a standard TCU, this is possible thanks to the smart cooling and cavity’s passive heating.

What our experts say

“The adoption of Microgel Syncro has offered us the possibility of winning an order that we would otherwise have lost. The reduction in cycle time, waste and dead times has allowed us to significantly lower production costs.”

“Why should a cycling process like Injection Moulding be cooled via constant flow? Our answer to this question is: Microgel Syncro. The first unit that understand the process, providing cold water only when needed. This approach guarantees benefits in cycle reduction and quality of the products. Welcome in the new era of thermoregulation!”

“After 30 years of Microgel technology, process cooling is again improving with the introduction of Microgel Syncro. The integration of the cooling approach with the molding machine is the core of this unit. We wanted to develop it with an advanced syncronized technology, suppported by an intuitive HMI and proven performance. Take advantage of Microgel Syncro to improve your process!”

“Syncro technology solves the technical injection molding compromise between productivity and quality, making the mold cooling as cyclic as the process itself. This turns into maximizing productivity, quality and energy efficiency.”

“The apparently crazy idea to cool only when and only how much needed and to exploit the residual heating to bring the mold surface to the required temperature, proved to be winning. The results on field are definetely over my expectations!”

“Since the beginning our Microgel has helped many injection molders achieve significant cycle time reductions. We felt we needed to go further exploiting the two key elements of our experience, flow rate and temperature management, in different ways. We also wanted to push the cycle time reduction into molding applications where part quality constraints were the limitation. We did it by simply synchronizing the heat extraction with the molding cycle.”

Come and visit us at the upcoming events

K-SHOW

Germany (Dusseldorf). Frigel presents its innovative Thermal Control Technology focused on Cycle Time Reduction.

CHINAPLAS

China. Frigel's latest process cooling solutions focused on Plastic & Rubber Industry.

INTERPLAST

Thailand (Bangkok). Frigel's Thermal Control Solutions & Ecodry Coolers for the Asian market.

FAKUMA

Germany (Friedrichafenn). Frigel's Innovative Process Cooling Solutions focused on Plastic Industries.

Syncro technology to improve quality and production

SOLUTION

GelliPlast, like Frigel, confirms itself as a company focused on customer care.

IMPACT

It dedicates significant investments in cutting-edge technology, analysis and research.

Syncro technology to improve quality and production

SOLUTION

GelliPlast, like Frigel, confirms itself as a company focused on customer care.

IMPACT

It dedicates significant investments in cutting-edge technology, analysis and research.

Syncro technology to improve quality and production

SOLUTION

GelliPlast, like Frigel, confirms itself as a company focused on customer care.

IMPACT

It dedicates significant investments in cutting-edge technology, analysis and research.